|

|

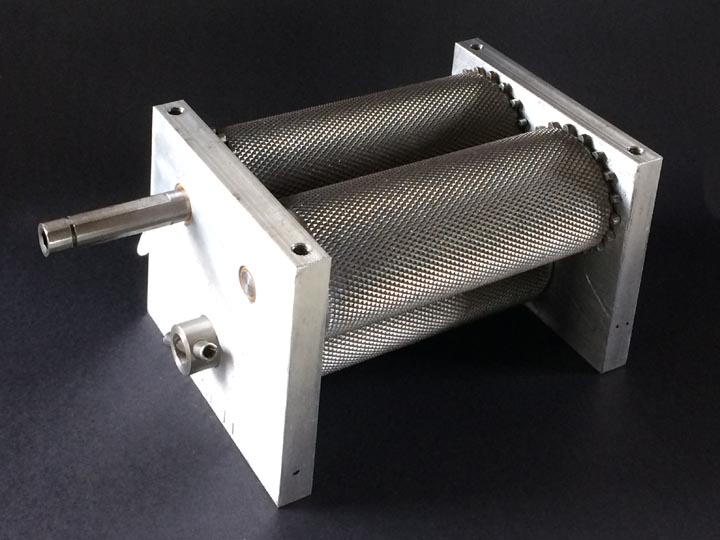

Components for the mechanically adept entrepreneur and hobbyist

We're here to save you money without compromising valuable features and performance.

Startup costs for a brewery or chocolate shop can be pretty steep, especially when pricing new equipment

from manufacturers that are also trying to recoup the development costs of their new product lines.

You can keep the process flexible and within budget by designing things to fit your ideas rather than theirs.

The index adjusters alone are reason enough to choose these mills.

But that's just one of the features that sets them apart:

Tool-steel driveshafts

High tensile steel axles

Application specific knurling

Case hardened alloy steel gears

Full complement gearing

Material choices optimized for longevity

Completely rebuildable design

Quality inspection throughout manufacture

A range of applications has sharpened our knowledge of what works best.

Rather than theory, we've got nearly three decades of real world results backing it up.

Here's a link to some setup suggestions:

https://byo.com/project/motorize-your-grain-mill-projects/

This review is more recent than most and highlights the newer features:

https://www.homebrewtalk.com/threads/crankandstein-3gt.694039/

Featured Products

320G$350.00 320G$350.00

|